The idlers are playing a important part in the belt conveyor system.

They consist in the entire transport process to support the belt and move the materials loaded on the belt.

Product Characteristics:

The idler is composed of

eight parts, which is bearing,stamped bearing housing,cold drag

axle,circlip for axle,steel wire circlip for axle,first labyrinth style

sealing,second labyrinth style sealing and cover.

The idler is made of special fine welding steel pipe and we do puncture process in the tube. We control roundness in special tolerance scope. The axle is made according to standard tolerance and manufactured by fine cold drag steel. The bearing housing has been manufactured after stamping many times by the imported cold griped steel.

Detailed conveyor idler feature:

1.

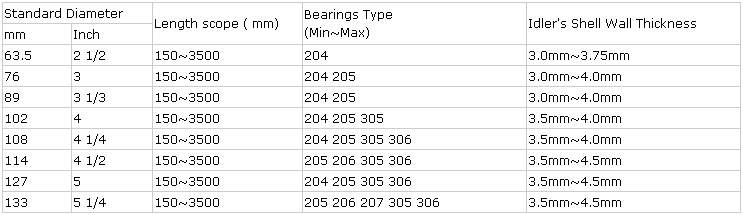

Roller idlers Dia 76mm-219mm, length 190-3500mm, which are used in the

steel in dustry, harbor, coal industry, power in dustry, cement

industry, etc

2. Tube: Q235

3. Shaft: 45# STEEL

4. Bearing: Single & Double Row Deep Groove Ball Bearing 2RZ&2Z with C3 clearance.

5.

Seals: Grease retaining inner seal with Multi-stage Labyrinth and

Retention Cap with Outboard Rubbing Flinger Seal.Special design and

particular labyrinthine seal style prevent the corrosion by impurity,

water and air etc.

6. Lubrication: Grease is Lithium soap type grease with Rust Inhibitors.

7. Welding: Mixed gas shielded arc welding end.Fine welding tube ensure the rollers with low vibration and noise.

8. Working life: 30,000 - 50,000 hours.

9.Standard:CEMA/JIS/DIN